What is Minimum Bend Radius & Why Does It Matter?

The minimum bend radius is the smallest curve a hose can be bent without causing damage, kinking, or flow restriction. Bending a hose too tightly can lead to:

❌ Restricted Flow – Kinks reduce efficiency and increase pressure buildup.

❌ Structural Weakening – Excessive bending weakens the hose walls, leading to failure.

❌ Leaks & Ruptures – Over time, improper bending can cause hazardous failures.

Factors That Affect Minimum Bend Radius

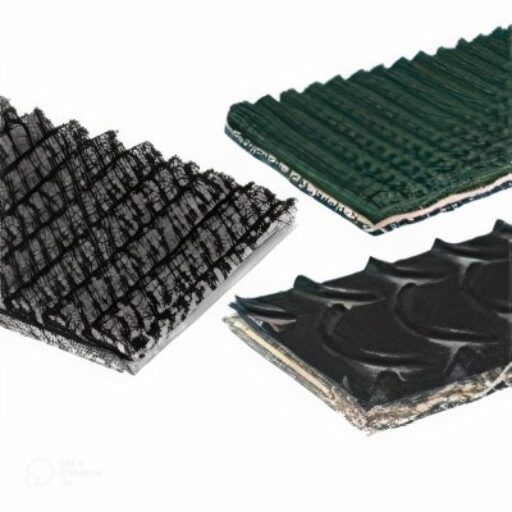

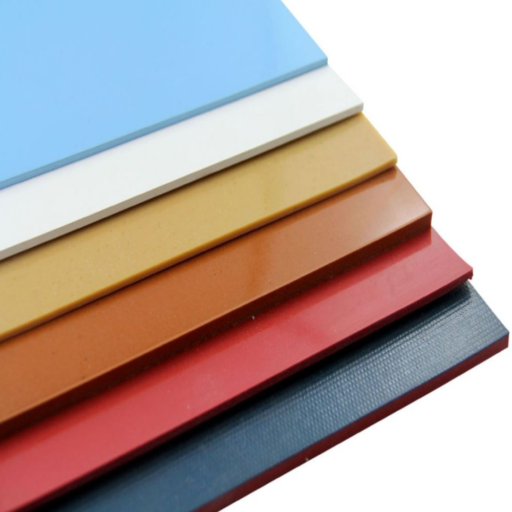

🔹 Material Type – Rubber hoses are more flexible, while metal and thermoplastic hoses require larger bend radii.

🔹 Reinforcement Layers – Braided vs. spiral-wound reinforcements impact flexibility.

🔹 Temperature Conditions – Extreme heat softens hoses; extreme cold causes stiffness.

🔹 Pressure Rating – Higher-pressure hoses require a larger bend radius.

Best Practices for Proper Hose Installation

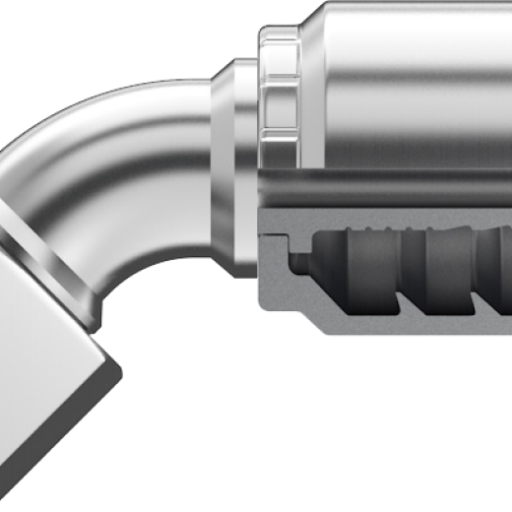

✔ Use the Largest Possible Bend Radius – Allow hoses to curve naturally.

✔ Avoid Sharp Bends Near Fittings – Maintain at least 18 inches of straight hose before bends.

✔ Use Hose Supports & Clamps – Prevent sagging and excessive bending.

✔ Factor in Temperature & Pressure – Select hoses designed for real-world conditions.

✔ Inspect Hoses Regularly – Look for signs of stress, leaks, or damage before failure occurs.

Maximizing Hose Lifespan – Care, Maintenance & Storage

Keeping your hoses in top condition is essential for safety, efficiency, and cost savings. Proper care and maintenance can extend the lifespan of your hoses, preventing unexpected failures and costly downtime. Here’s how you can keep your hoses performing at their best.

How to Extend the Life of Your Hose

One of the most important things you can do is avoid excessive bending. Sharp bends can weaken the hose structure over time, leading to premature wear. It’s also crucial to manage temperature exposure—make sure your hose is rated for both the fluid it carries and the surrounding environment.

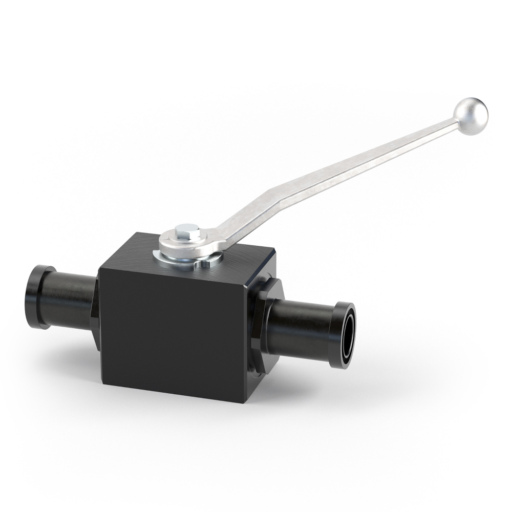

Pressure surges are another factor that can damage hoses, so always open and close valves gradually to prevent sudden spikes. Choosing the right hose for the job is equally important—verify chemical compatibility before use to avoid material degradation. Lastly, don’t forget about UV and weather exposure. Prolonged sunlight and moisture can break down hose materials, so proper protection is key.

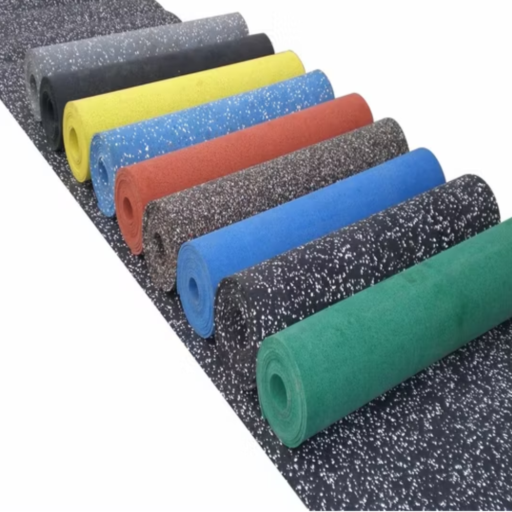

Best Practices for Hose Storage

Storing your hoses correctly is just as important as using them properly. Always keep them in a cool, dry place, away from direct sunlight and extreme temperatures. Following a FIFO (First In, First Out) rotation system helps prevent older hoses from sitting unused for too long, which can lead to deterioration. Another simple yet effective tip—cap hose ends when not in use to keep out dirt and contaminants.

Why Regular Inspections Matter

Routine inspections are essential for maintaining hose performance and safety. Regularly check for signs of wear and tear, such as cracks, leaks, or swelling. Pay close attention to fittings, ensuring they are secure and free from corrosion. If you spot any damage, don’t wait—replacing a worn hose before it fails can save you from costly downtime and potential safety hazards.

Need a Hose Management Plan?

Managing hose maintenance doesn’t have to be a challenge. Catawba Rubber offers customized hose management programs to help businesses track maintenance schedules, extend hose lifespan, and prevent unexpected failures. Contact us today to learn more!