North Carolina’s food production industry is fast-paced and demanding, requiring high-performance conveyor belting solutions that prioritize efficiency, hygiene, and durability. From dairy processing to large-scale bakery production and seafood processing along the Atlantic Coast, food manufacturers rely on premium lightweight conveyor belts to maintain smooth and sanitary operations.

At Catawba Rubber, we supply a wide range of industry-leading belting solutions from top manufacturers like Habasit, Modutech, and Volta, ensuring that food processors meet the highest standards for safety, efficiency, and compliance.

Habasit: Excellence in Food-Grade Conveyor Belts

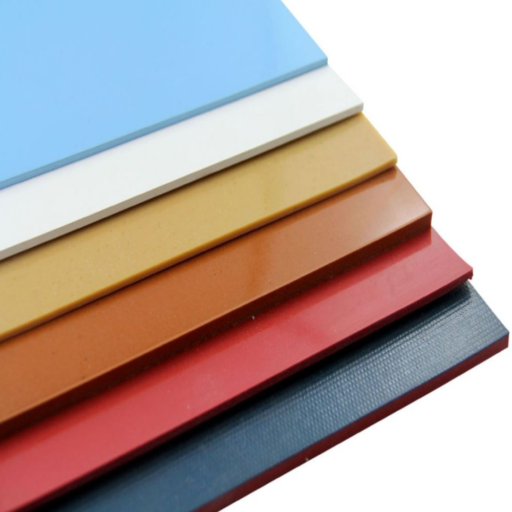

Habasit is a globally recognized leader in food-safe conveyor belting, offering high-performance solutions for meat and poultry processing, dairy production, and bakery operations. Their TPU and PVC food-grade belts are designed for superior wear resistance, oil and fat resistance, and full compliance with FDA and USDA regulations.

For food processors in North Carolina, Habasit’s lightweight conveyor belts help:

✔ Reduce maintenance downtime

✔ Improve sanitation efficiency

✔ Enhance food safety standards

Whether you are handling fresh dairy, baked goods, or ready-to-eat meals, Habasit provides reliable, easy-to-clean conveyor belt solutions for demanding food processing environments.

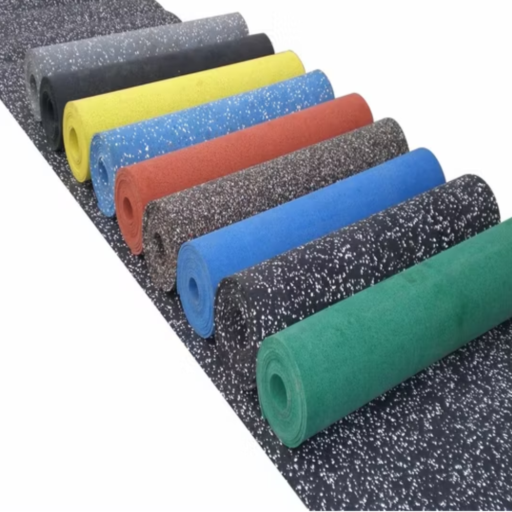

Modutech: Modular Plastic Conveyor Belt Solutions for Food Processing

Modutech specializes in modular plastic conveyor belts designed for applications requiring high flexibility, durability, and easy cleaning. These belts are widely used in:

- Fresh fruit & vegetable processing – Ideal for produce washing, sorting, and packaging.

- Seafood processing – Corrosion-resistant belts for handling wet and frozen products.

- Snack food & frozen food production – Customizable designs for diverse applications.

The modular design of Modutech belts allows for quick repairs, easy customization, and long-term cost savings, making them a top choice for high-output facilities. Food manufacturers in North Carolina, from seafood processors to fruit and vegetable packers, trust Modutech for hygienic and heavy-duty conveyor solutions.

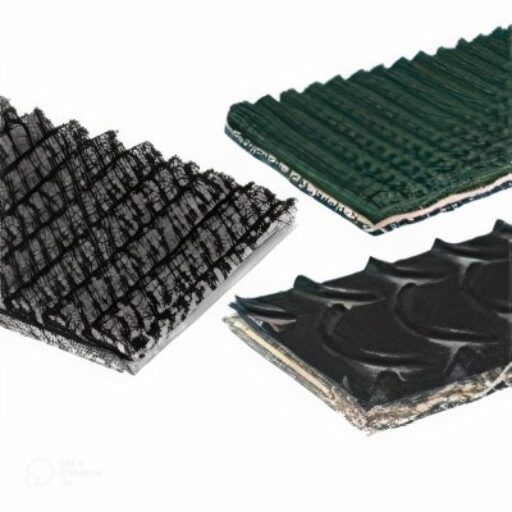

Volta: Thermoplastic Belting for Superior Hygiene

Volta’s thermoplastic conveyor belts are revolutionizing food processing operations by eliminating traditional fabric layers that harbor bacteria and contaminants. These solid homogeneous belts offer:

✔ Zero fabric layers – Prevents microbial growth and contamination.

✔ Superior durability – Withstands heavy-duty food processing conditions.

✔ Easy cleanability – Reduces downtime and improves sanitation.

Volta belts are particularly beneficial for industries requiring strict hygiene and food safety compliance, including:

- Meat and poultry processing

- Cheese and dairy production

- Confectionery and snack food manufacturing

For food manufacturers in North Carolina, Volta’s cutting-edge belting technology helps businesses maintain FDA, USDA, and HACCP compliance, ensuring the highest level of food safety.

Why Choose Catawba Rubber?

At Catawba Rubber, we understand the unique challenges of food production. Our high-quality conveyor belts from Habasit, Modutech, and Volta help food processors maintain:

✔ Efficiency – Reduce downtime and maximize productivity.

✔ Hygiene – Meet strict food safety and sanitation standards.

✔ Compliance – Ensure full FDA, USDA, and HACCP compliance.

Whether you operate in dairy, fresh produce, bakery, or seafood processing, our expert team can help you select the right conveyor belting solution for your facility.

Contact Catawba Rubber Today!

Looking for reliable, food-safe conveyor belting solutions? Contact Catawba Rubber today to learn more about how our lightweight conveyor belts can enhance your food production operations across North Carolina!