Custom Gasket Cutting Services

Custom Gaskets & Sealing Solutions by Catawba Rubber

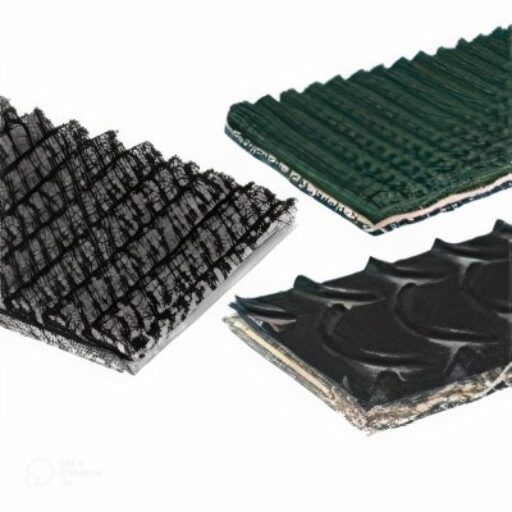

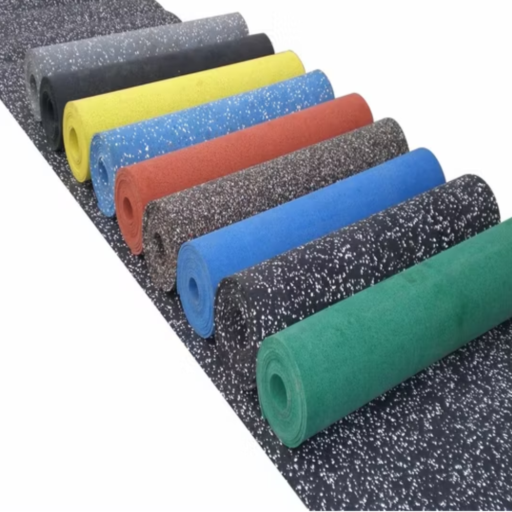

At Catawba Rubber, we provide a wide range of sealing products, from roll sheet goods to Teflon-lined metal expansion joints. Our expert team is ready to assist you with custom gasket fabrication for any application. We manufacture custom gaskets up to 60” in diameter and thicknesses up to 2” using state-of-the-art gasket cutting equipment, ensuring precision and reliability.

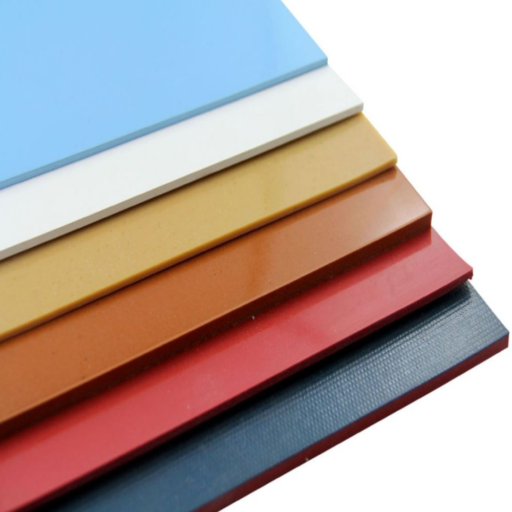

Our extensive material selection includes (but is not limited to):

Teflon

Neoprene

Red Rubber

SBR

EPDM

Buna

Graphite

Viton

MIL-SPEC Rubber

Our high-performance materials are designed to handle seal pressures up to 3,000 psi and withstand extreme temperatures ranging from cryogenic levels to 2,000°F.

Contact us today to discuss your custom gasket and sealing needs!

Custom Gasket Cutting

Catawba Rubber: Precision Custom Gasket Cutting for Industrial Applications

At Catawba Rubber, we specialize in precision custom gasket cutting for a wide range of industrial applications. Whether you need standard or custom-designed gaskets, we provide high-quality materials, precise cutting methods, and fast turnaround times to meet your exact specifications. Our state-of-the-art cutting technology ensures that every gasket is produced with superior accuracy, consistency, and performance, helping you achieve leak-free and reliable sealing solutions.

Common Questions About Custom Gasket Cutting

- What is custom gasket cutting?

Custom gasket cutting is the process of fabricating gaskets to meet specific shapes, sizes, and material requirements. Unlike off-the-shelf gaskets, custom-cut gaskets ensure a perfect fit for unique applications, providing superior sealing, durability, and performance. - What types of materials can Catawba Rubber cut for custom gaskets?

We offer a wide selection of high-performance gasket materials, including:

Rubber (EPDM, neoprene, nitrile, silicone, Viton®)Compressed non-asbestos sheets

PTFE (Teflon®) and expanded PTFE

Graphite and high-temperature materials

Cork, felt, and sponge rubber

Metallic and semi-metallic materialsOur team can help you select the best material based on chemical resistance, temperature, pressure, and application needs. - What industries require custom gaskets?

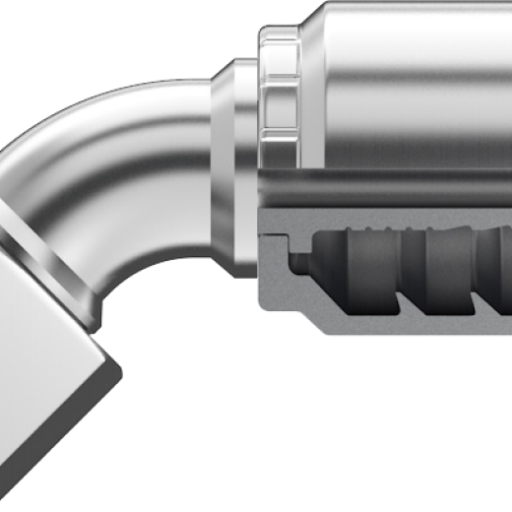

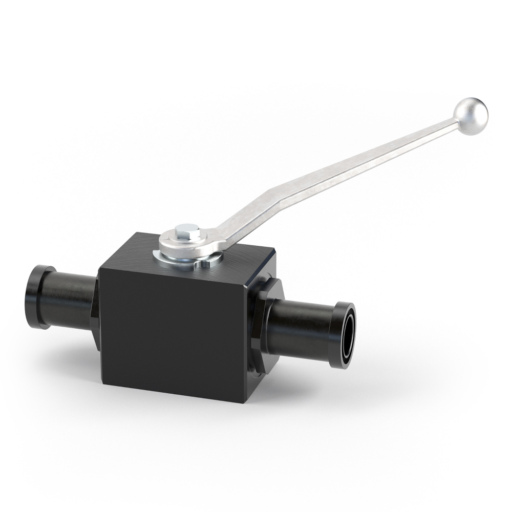

Custom gasket cutting is essential for industries that rely on precise sealing solutions, including:Manufacturing & industrial processing – Custom gaskets for pumps, valves, and machinery.

OEM & equipment fabrication – Seals and gaskets tailored to custom designs.

Oil & gas – High-temperature and chemical-resistant gaskets for refineries.

Construction & HVAC – Sealing solutions for air, fluid, and gas handling systems.

Food & beverage processing – FDA-approved gaskets for sanitary applications.

Pharmaceutical & chemical industries – Precision-cut gaskets for containment and processing. - What cutting methods does Catawba Rubber use for custom gaskets?

We utilize advanced cutting technologies to ensure precision and efficiency, including:Die cutting – Ideal for high-volume production of uniform gaskets.

Flash cutting – A fast, tool-free method for rapid prototyping and low-volume runs.

Waterjet cutting – Precise, clean cuts without heat distortion, perfect for intricate designs.

Knife cutting – A cost-effective option for soft materials.

Why should I choose custom-cut gaskets over standard gaskets?

While standard gaskets work for common applications, custom-cut gaskets offer several advantages, including:Perfect fit – Designed to match exact dimensions and specifications.

Better performance – Reduces leaks and enhances sealing capabilities.

Material flexibility – Choose the right material for temperature, pressure, and chemical resistance.

Cost savings – Prevents equipment damage and downtime from poor-fitting seals. - How quickly can Catawba Rubber produce custom gaskets?

We offer fast turnaround times, with many custom gaskets available same-day or next-day, depending on material availability and complexity. For urgent needs, our team can provide expedited cutting services to minimize downtime. - Can Catawba Rubber produce prototype gaskets?

Yes! We offer rapid prototyping services using our precision cutting technology, allowing you to test and refine gasket designs before full production. - Do you provide large-volume gasket production?

Absolutely! Whether you need a single custom gasket or high-volume production, Catawba Rubber has the capabilities, materials, and expertise to meet your demands.

Catawba Rubber: Your Trusted Partner for Custom Gasket Cutting

With precision cutting technology, high-quality materials, and expert craftsmanship, Catawba Rubber ensures that your custom gaskets provide the perfect seal, every time.

Need a custom gasket? Contact us today for expert consultation and fast service!