Industrial Hose Production Services

Catawba Rubber: Precision Crimping & Custom Hose Solutions for North Carolina Industries

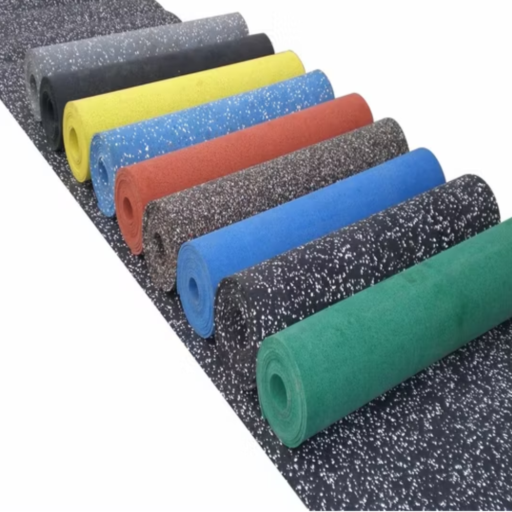

At Catawba Rubber, we offer industry-leading crimping capabilities to support your hose needs with precision, efficiency, and reliability. With the ability to crimp hoses up to 8 inches in diameter, our advanced production facilities and Charlotte-based distribution center ensure we can deliver high-quality, custom-fabricated hoses tailored to your exact specifications. Whether you need a single hose assembly or large-scale production, we have the equipment, expertise, and infrastructure to meet your needs quickly and efficiently across North Carolina.

We understand that hoses are critical components in a wide range of industries, which is why we specialize in providing a full spectrum of solutions, including:

✔️ Food & Beverage Hose

✔️ Chemical Transfer Hose

✔️ Water Suction & Discharge Hose

✔️ Compressed Air Hose

✔️ Steam Hose

✔️ Oil & Fuel Transfer Hose

✔️ Specialized Industrial Applications

No matter the industry or application, our team is dedicated to delivering the right hose, at the right time, for any size job.

With a reputation built on exceptional service, fast turnaround times, and reliable supply chain management, Catawba Rubber is your trusted partner for high-performance hose solutions in North Carolina. Our extensive inventory and strategic East Coast distribution ensure you receive the right products when you need them, minimizing downtime and keeping your operations running smoothly and efficiently.

When you choose Catawba Rubber, you’re choosing a partner that delivers quality, expertise, and on-time solutions—every time. Contact us today and experience the Catawba Rubber difference!

Best In Class Industrial Hose Crimping

Why Crimping Is the Superior Choice for Industrial Hoses

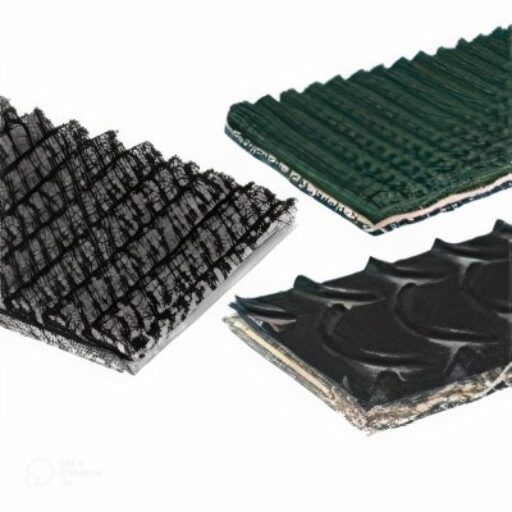

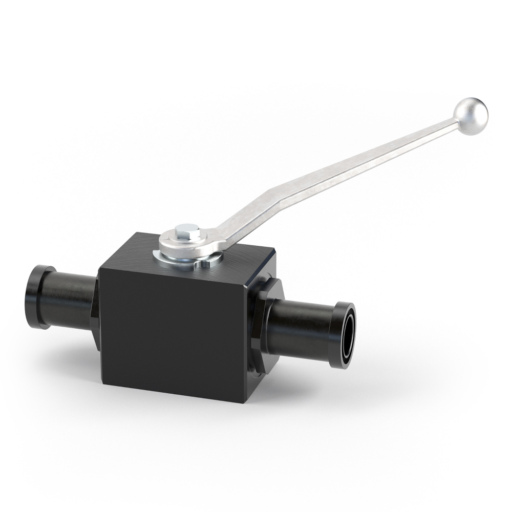

When securing industrial hoses, two primary methods are used: crimping and clamping. While both have their place, crimping is the preferred choice for most industrial, hydraulic, and high-pressure applications due to its unmatched strength, reliability, and long-term durability. A properly crimped hose provides a leak-proof, secure connection, ensuring maximum safety and efficiency in demanding environments.

Why Choose Crimping Over Clamping?

Stronger & More Secure Connection – Crimping evenly compresses the metal ferrule around the hose fitting, creating a tight, uniform seal that resists leaks, blow-offs, and failures under high pressure.

Enhanced Safety – Crimped hoses are far less likely to loosen or detach, significantly reducing the risk of accidents in high-pressure environments like hydraulic systems, industrial fluid transfer, and chemical transport.

Superior Durability – A crimped connection outperforms clamps in vibration-heavy, high-temperature, and chemically harsh conditions, providing long-lasting performance without the risk of loosening over time.

Leak Prevention – Unlike clamps, which rely on manual tightening and may loosen under pressure, temperature fluctuations, or movement, crimped fittings form a permanent, factory-quality seal, minimizing costly maintenance and downtime.

Precision & Customization – Crimping allows for exact pressure ratings and hose sizes, ensuring a consistent, high-quality connection designed for the specific application.

Industry Compliance – Many industries, including oil & gas, food processing, pharmaceuticals, and chemical transport, require crimped hose assemblies to meet strict safety and performance standards.

When to Use Clamping Instead of Crimping

While crimping is the gold standard for industrial hoses, clamping may still be used in select situations, such as:

Low-pressure applications where minor adjustments may be needed.

Temporary or emergency repairs that require a quick fix.

Non-critical hose assemblies where pressure and safety regulations are less stringent.

FAQs About Hose Crimping

✅ What is hose crimping?

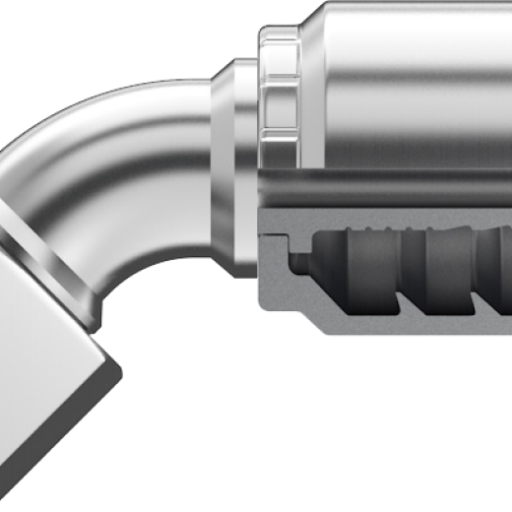

Hose crimping is a precision process that permanently secures a hose fitting using a hydraulic or pneumatic crimping machine. The machine compresses a metal sleeve (ferrule) over the hose and fitting, creating a strong, leak-proof connection.

✅ How does crimping compare to traditional hose clamping?

Crimping delivers a stronger, more reliable, and permanent connection, whereas clamps require manual tightening and may loosen over time, increasing the risk of leaks and failures.

✅ Which industries require crimped hoses?

Crimping is essential in industries such as hydraulics, manufacturing, food and beverage processing, pharmaceuticals, oil & gas, and chemical transport, where safety, precision, and high performance are critical.

✅ Can crimped hoses be reused?

No, crimped hoses are designed as a one-time assembly. If a hose needs replacing, a new hose and fitting must be crimped for proper function and safety.

✅ Do crimped hoses require special equipment?

Yes, crimping requires a hydraulic or pneumatic crimping machine to achieve a secure, factory-quality connection that meets pressure and safety standards.

✅ What are the risks of using clamped hoses instead of crimped hoses?

Clamped hoses are more prone to loosening due to vibration, temperature changes, and fluctuating pressure, which can lead to leaks, system failures, and potential safety hazards.

✅ Are crimped hoses more expensive than clamped hoses?

While crimping may have a higher initial cost, the long-term benefits—including reduced maintenance, improved safety, and increased hose lifespan—far outweigh the expense.

✅ Can all hoses be crimped?

Not all hoses are designed for crimping. Some low-pressure hoses may be suitable for clamping, but the majority of industrial, hydraulic, and high-performance hoses are best secured with crimping.

Crimping: The Smart Choice for Performance, Safety & Compliance

By choosing crimping over clamping, businesses ensure their industrial hoses perform at the highest level—with superior strength, reliability, and compliance with industry standards. At RW Connection, we provide expertly crimped hose assemblies designed for maximum durability and efficiency.

Contact us today to get the right crimped hose solution for your operations!