Conveyor Mobile Maintenance Services

Catawba Rubber Mobile Maintenance – On-Site Repairs & Fabrication Services

At Catawba Rubber, we provide Mobile Maintenance for all your on-site repairs, metal installations, fabrications, and machine shop needs. With 200+ years of combined conveyor and industrial experience, our team has the expertise and skills to handle your mobile maintenance requirements with precision and efficiency.

We offer a full range of services, from small welding repairs on your system to complete turnkey system builds. Our team includes certified welders and fabricators, ensuring high-quality, competitively priced metalwork for both planned outage repairs and 24/7 emergency services.

When combined with our preventative maintenance services, our Mobile Maintenance program helps:

Extend the longevity of repairs

Reduce overall maintenance costs

Minimize downtime for critical systems

Whether you need routine maintenance, emergency repairs, or custom fabrication, Catawba Rubber is your trusted partner for on-site industrial solutions.

Contact us today to discuss your mobile maintenance needs!

Conveyor Mobile Maintenance

Catawba Rubber: On-Site Conveyor Mobile Maintenance Services in North Carolina

At Catawba Rubber, we know that minimizing downtime is crucial to keeping your operations running efficiently and profitably. Our Conveyor Mobile Maintenance service brings expert technicians, specialized tools, and high-quality materials directly to your site, providing on-demand repairs, preventative maintenance, and emergency response—where and when you need it.

Common Questions About Conveyor Mobile Maintenance

- What is Conveyor Mobile Maintenance?

Conveyor Mobile Maintenance is an on-site service where our trained field technicians inspect, repair, and maintain conveyor systems directly at your facility. Instead of waiting for failures, our mobile service team ensures your conveyor belts remain in peak condition, reducing the risk of costly unplanned downtime. - What types of services are included in Catawba Rubber’s mobile maintenance program?

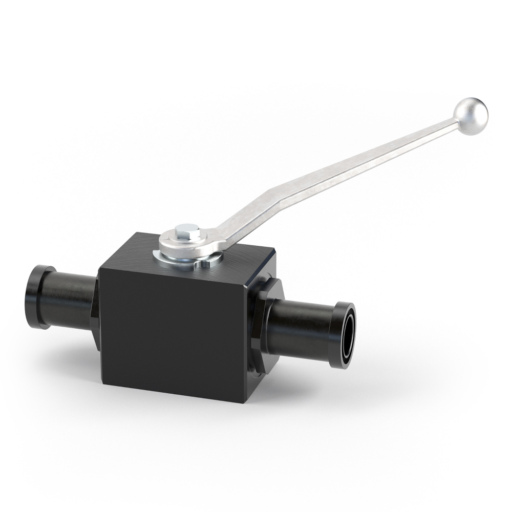

Our fully equipped mobile units provide a comprehensive range of on-site conveyor services, including:

Routine belt inspections & system surveys – Identifying wear, misalignment, and potential failures before they happen.

Preventative maintenance programs – Scheduled services to extend belt life and optimize efficiency.

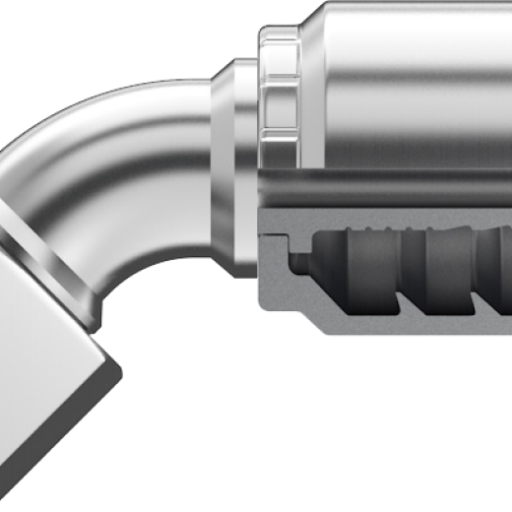

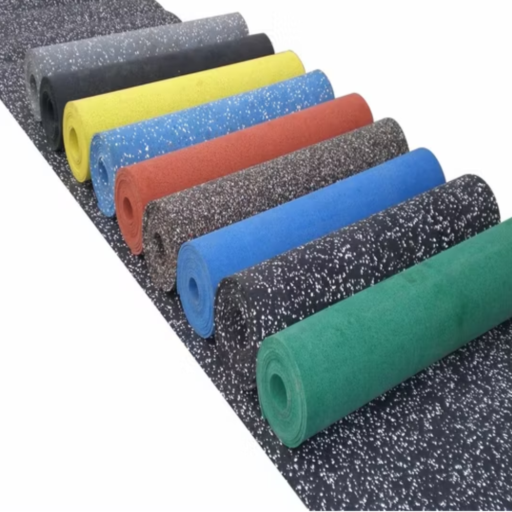

On-site belt repairs & splicing – Hot and cold vulcanization, mechanical fasteners, and patching to keep your belt running.

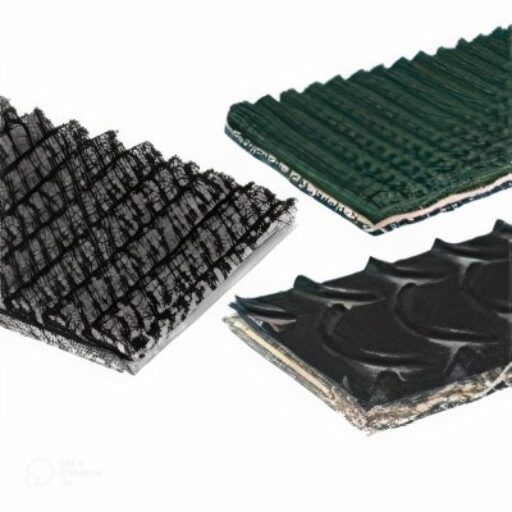

Pulley lagging, chute lining, and skirtboard installation – Enhancing belt performance and reducing material loss.

Emergency breakdown service – 24/7 rapid response to minimize downtime and restore production quickly.

- Why is mobile maintenance important for conveyor systems?

Conveyor systems operate under high stress and constant use, making regular maintenance essential. Mobile maintenance provides:

Immediate on-site service, reducing the need for transporting equipment off-site for repairs.

Proactive solutions, catching potential issues before they become costly failures.

Reduced downtime, keeping your operation running efficiently.

Improved safety, ensuring belts and components meet industry standards.

- How often should conveyor systems undergo mobile maintenance?

The ideal maintenance schedule depends on usage, application, and environmental conditions. We recommend:

Regular monthly inspections for systems under heavy use.

Quarterly preventative maintenance to extend the lifespan of belts and components.

Immediate service if you notice tracking issues, excessive wear, or belt slippage.

- Can mobile maintenance services handle emergency conveyor repairs?

Yes! Our 24/7 emergency mobile response team is ready to handle unexpected breakdowns and belt failures. We quickly diagnose the issue, provide fast repairs, and get your system back online with minimal disruption to your operations. - What industries benefit from Conveyor Mobile Maintenance?

Our mobile conveyor services are ideal for industries that depend on continuous material handling, including:

Aggregates & mining – Ensuring heavy-duty belts handle abrasive materials efficiently.

Manufacturing & distribution – Reducing downtime in production and automated facilities.

Recycling & waste management – Repairing and maintaining high-impact conveyor belts.

Power generation – Keeping coal, biomass, and ash-handling belts running smoothly.

Pulp & paper – Maintaining fast-moving production lines with minimal disruptions.

Catawba Rubber: Your Trusted Partner for On-Site Conveyor Maintenance

With experienced technicians, state-of-the-art mobile service units, and a commitment to keeping your operations running smoothly, Catawba Rubber provides the best Conveyor Mobile Maintenance services in North Carolina.

Need on-site conveyor maintenance? Contact Catawba Rubber today to schedule an inspection or emergency repair!