Belt Safety & Training Services

Catawba Rubber: Safety-Driven Conveyor Services You Can Trust

At Catawba Rubber, safety is not just a priority—it’s the foundation of everything we do. Our field service crews are MSHA Part 48 Above Ground Certified and operate within a “Zero Incident” culture, ensuring that every project is completed with the highest level of safety and professionalism. Each team member undergoes rigorous in-house training to master the proper techniques for inspecting, splicing, vulcanizing, and installing conveyor belts, guaranteeing precision and reliability in every service we provide.

Beyond MSHA certification, we are also fully compliant with BROWZ, PICS, and ISN.net, meeting the most stringent industry safety and compliance standards. When choosing a service crew, you need professionals who are not only highly skilled but also dedicated to maintaining a safe work environment. At Catawba Rubber, you can trust that our experts will get the job done right—efficiently, safely, and in full compliance with industry regulations.

With a reputation built on dependability, we are proud to be your Safe, Fast, and Reliable service provider, available 24/7/365 to keep your operations running smoothly. No matter the challenge, Catawba Rubber is here to deliver exceptional service with an unwavering commitment to safety and efficiency.

Contact us today to learn more about our safety-driven conveyor services!

Belt Safety & Training

Catawba Rubber: Comprehensive Belt and Safety Training Programs

At Catawba Rubber, we believe that proper training is the foundation of a safe and efficient workplace. Our Belt and Safety Training programs provide hands-on instruction in conveyor belt maintenance, splicing techniques, and workplace safety standards. By equipping your team with the knowledge and skills needed to operate, maintain, and repair conveyor systems safely, we help reduce downtime, prevent accidents, and extend equipment life.

Common Questions About Belt and Safety Training

- What is Catawba Rubber’s Belt and Safety Training?

Our Belt and Safety Training programs are designed to educate personnel on best practices for conveyor belt installation, maintenance, and safety compliance. We offer both classroom and hands-on training, ensuring that employees gain the technical knowledge and practical experience needed to prevent failures and maintain a safe working environment. - What topics are covered in the training?

Our training programs cover a wide range of essential topics, including:

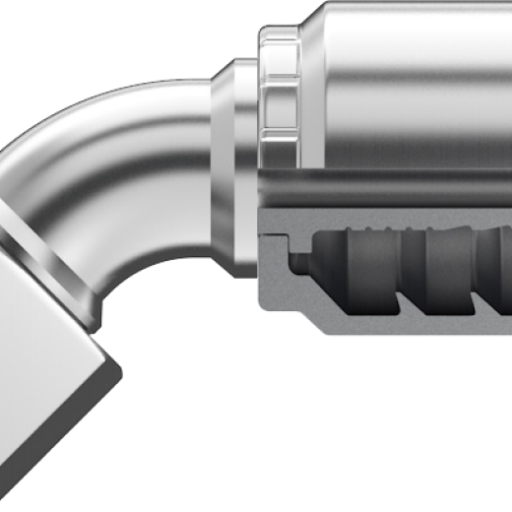

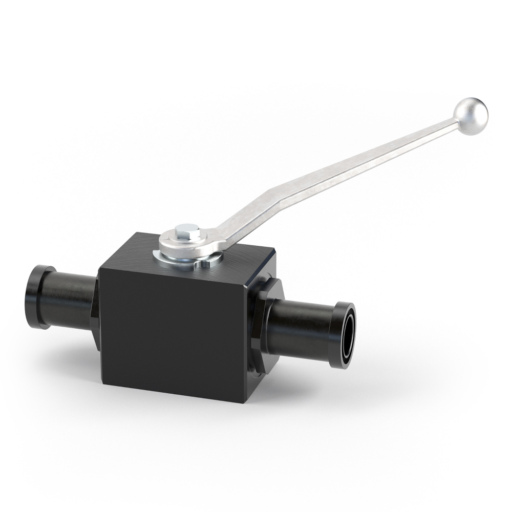

Conveyor belt installation and tracking – Ensuring proper alignment and tensioning for maximum efficiency.

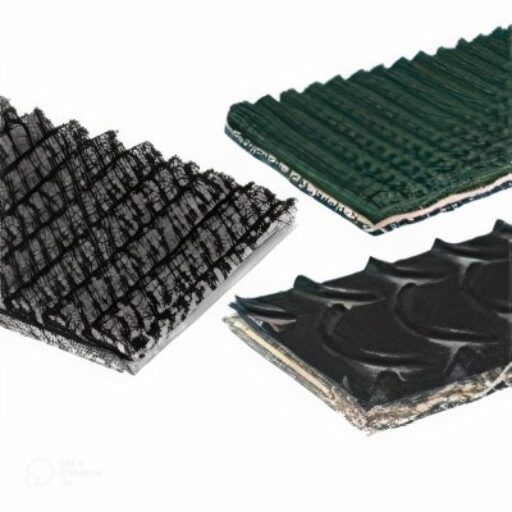

Splicing techniques (hot & cold vulcanization, mechanical splicing) – Understanding when and how to apply different splicing methods.

Preventative maintenance practices – Identifying wear patterns, common failures, and proactive maintenance strategies.

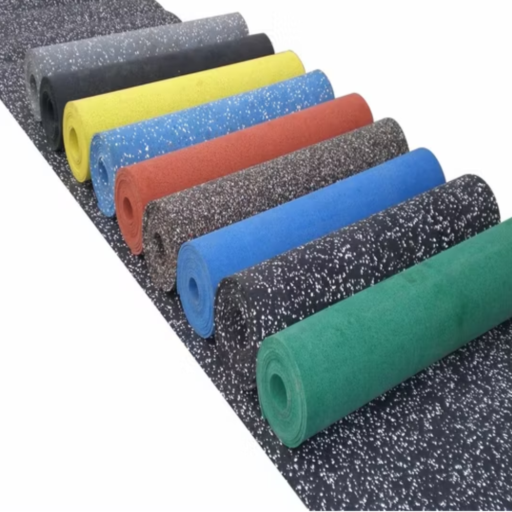

Pulley lagging, chute lining, and skirtboard management – Optimizing conveyor performance and reducing material loss.

Workplace safety and hazard identification – Compliance with OSHA, MSHA, and industry safety standards.

Emergency response training – How to handle belt failures, shutdowns, and restart procedures safely.

- Who should attend Belt and Safety Training?

This training is ideal for:

Maintenance personnel – Those responsible for inspecting and repairing conveyor systems.

Operations managers & supervisors – Ensuring teams follow best practices for belt maintenance and safety.

Equipment operators – Learning to recognize early signs of belt wear and failure.

Safety officers – Keeping the workplace compliant with safety regulations and standards. - Why is belt and safety training important?

Proper training ensures:

Safer workplaces – Reducing injuries, accidents, and compliance violations.

Fewer breakdowns – Identifying potential issues before they cause downtime.

Longer equipment life – Extending the lifespan of conveyor belts through proper care.

Increased productivity – Reducing unplanned downtime and improving operational efficiency.

- Can the training be customized for my facility?

Yes! We offer customized training programs tailored to your industry, equipment, and specific operational challenges. Training can be conducted on-site at your facility or at one of our training centers, ensuring maximum relevance and effectiveness. - Does Catawba Rubber provide certification for this training?

Yes! Upon completion of the training, participants receive a Certificate of Completion, demonstrating their proficiency in belt maintenance and safety protocols. - Which industries benefit from Belt and Safety Training?

Our training is essential for industries that rely on conveyor belt systems, including:

Aggregates & mining – Ensuring belts handle heavy loads safely.

Manufacturing & logistics – Keeping production lines running smoothly.

Recycling & waste management – Training workers on material handling safety.

Power generation – Teaching best practices for coal, biomass, and ash-handling systems.

Pulp & paper – Preventing conveyor failures in high-speed production environments.

Catawba Rubber: Your Partner in Conveyor Belt Training & Workplace Safety

By investing in Belt and Safety Training, companies can improve safety, extend equipment life, and boost operational efficiency. With experienced trainers and industry-specific programs, Catawba Rubber ensures your team has the knowledge and skills needed for success.

Ready to schedule a training session? Contact us today to learn more!