Modern data centers operate at unprecedented computing densities. The rise of AI workloads, GPU acceleration, and cloud-scale infrastructure has dramatically increased heat output per rack. Cooling systems—whether direct-to-chip liquid loops or rear-door heat exchangers—must keep pace without introducing risks to uptime or safety.

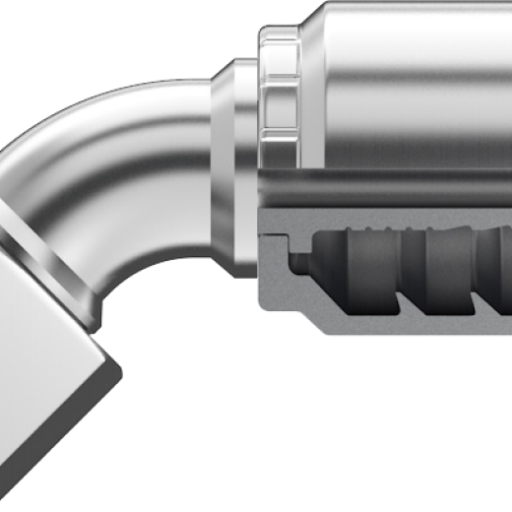

One often-overlooked component that can make or break cooling system performance is the coupler. Standard quick-connect couplers may introduce air on disconnect, leak coolant during maintenance, or create excessive pressure drop—all of which erode cooling capacity and efficiency.

CEJN® Smartflow Dry Break couplers, available through Catawba Rubber, are purpose-built for high-flow, zero-spill liquid cooling in mission-critical environments. They enable hot-swappable maintenance with no fluid loss, while maintaining maximum flow rates to protect server performance.

Key Advantages for Data Centers

1. Zero-Spill Disconnects

Smartflow’s dry break technology uses precision sealing to prevent coolant loss when disconnected, protecting sensitive electronics and preventing hazardous spills. This is critical for rack- and row-level servicing, where uptime is essential.

2. High Flow Rate Performance

Optimized internal geometry delivers minimal pressure drop across the coupler, enabling pumps to operate more efficiently and ensuring adequate coolant flow to all nodes in the loop. This is particularly valuable for long distribution loops in hyperscale environments.

3. Air Ingress Prevention

Traditional couplers risk introducing microbubbles into the system on reconnection. Smartflow’s design minimizes air ingress, reducing the risk of pump cavitation and maintaining stable thermal performance.

4. Durability and Compatibility

Constructed from corrosion-resistant materials, Smartflow couplers withstand continuous operation with common data center coolants, including water-glycol blends and dielectric fluids. They also handle repeated connect/disconnect cycles without performance degradation.

5. Compact, Lightweight Design

Smartflow’s space-saving form factor is ideal for high-density environments where rack space and hose routing flexibility are at a premium.

Impact on Uptime, Maintenance, and Cost

Switching to CEJN Smartflow couplers can dramatically reduce Mean Time to Repair (MTTR) for cooling system components. Because loops can remain sealed and pressurized during service, maintenance teams avoid full-system draining and refilling, saving hours of downtime and labor costs.

Energy Efficiency: Lower pressure drop reduces pump workload, which can yield measurable energy savings over time—especially in facilities with hundreds of cooling loops.

Environmental Responsibility: Preventing coolant loss minimizes waste and supports corporate sustainability initiatives.

Partnering with Catawba Rubber

As an authorized CEJN distributor, Catawba Rubber offers more than just product supply—we provide application engineering, system integration support, and lifecycle service for high-performance cooling solutions.

- Sizing Assistance: We ensure the coupler bore matches your desired flow rate and pressure profile.

- Material Compatibility Checks: We verify compatibility with specific coolant chemistries and environmental conditions.

- Retrofit Solutions: We help integrate Smartflow couplers into existing cooling loops with minimal disruption.

By combining CEJN innovation with Catawba Rubber’s technical expertise, we help data centers increase uptime, reduce operating costs, and future-proof their cooling infrastructure.

In a market where a single minute of downtime can cost thousands, CEJN Smartflow Dry Break couplers provide a high-flow, zero-spill connection solution that directly improves operational reliability. Whether for hyperscale cloud facilities, enterprise data centers, or high-performance computing clusters, upgrading to Smartflow with Catawba Rubber ensures safer maintenance, greater efficiency, and sustained cooling performance.

Frequently Asked Questions:

- How do Smartflow couplers prevent downtime?

They allow hot-swappable maintenance without coolant loss or air entry. - Are they compatible with glycol and dielectric coolants?

Yes—Smartflow is compatible with a range of liquid cooling fluids. - What sizes are available?

Multiple diameters are offered to match high-flow hose and pipe configurations. - Do they work with existing cooling loops?

In most cases, yes—they can be retrofitted with the right adapters.